All News

Glassy Carbon Technology for Ion Implantation Applications

06/05

2025

Glassy Carbon Technology for Ion Implantation Applications

Category: Semiconductor · Ion Implantation · Coating Technology

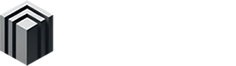

Performance Comparison of Graphite Materials

Key Advantages:

Ultra-high-purity impregnation and purification processes reduce total metallic impurity content to below 0.3 ppm and surface porosity to below 3.5%.

Advanced impregnation capabilities enable deep filling (up to 40 mm) and sealing of internal graphite pores, reducing particle generation and improving product quality.

High-performance glassy carbon coating technology eliminates residual particles and gas release on the graphite surface, improving surface hardness and wear resistance, and extending the service life of graphite components.

Glassy Carbon Performance in Ion Implantation

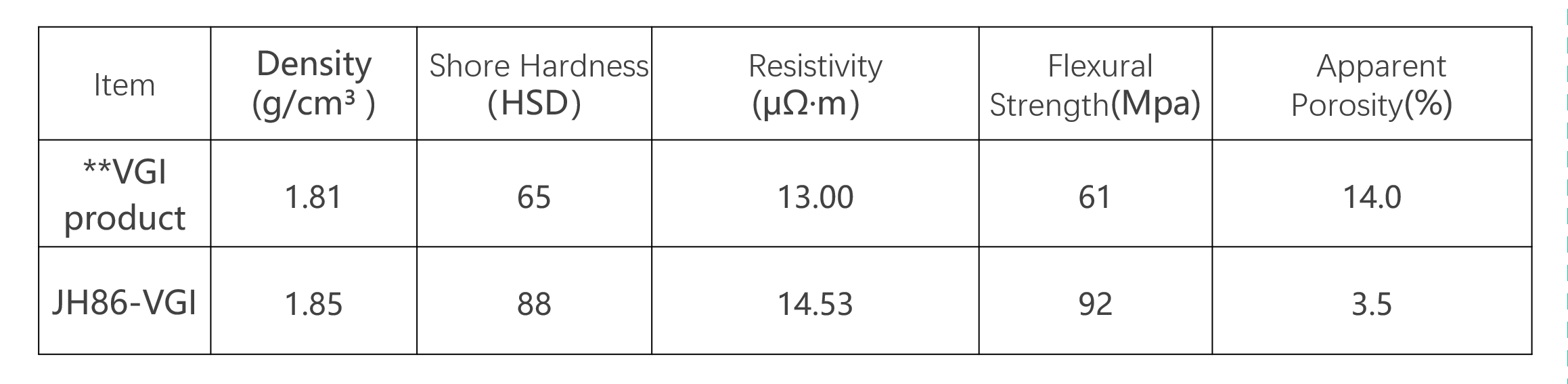

Comparison of Particle Distribution Before and After Cleaning:

The lower section shows particle maps before and after cleaning for graphite from different sources. Graphite Matrix’s material clearly shows less particle aggregation and improved particle dispersion after cleaning, indicating better quality and compatibility compared to other GCC-coated products.

Technology Highlight

To meet the specific requirements of H⁺ implantation processes, Graphite Matrix has preemptively developed and adopted a new-generation GCC coating technology. This advanced coating offers:

-

- Superior uniformity

- No glassy carbon peeling

- Enhanced resistance to erosion

- Reliable product performance and extended service life

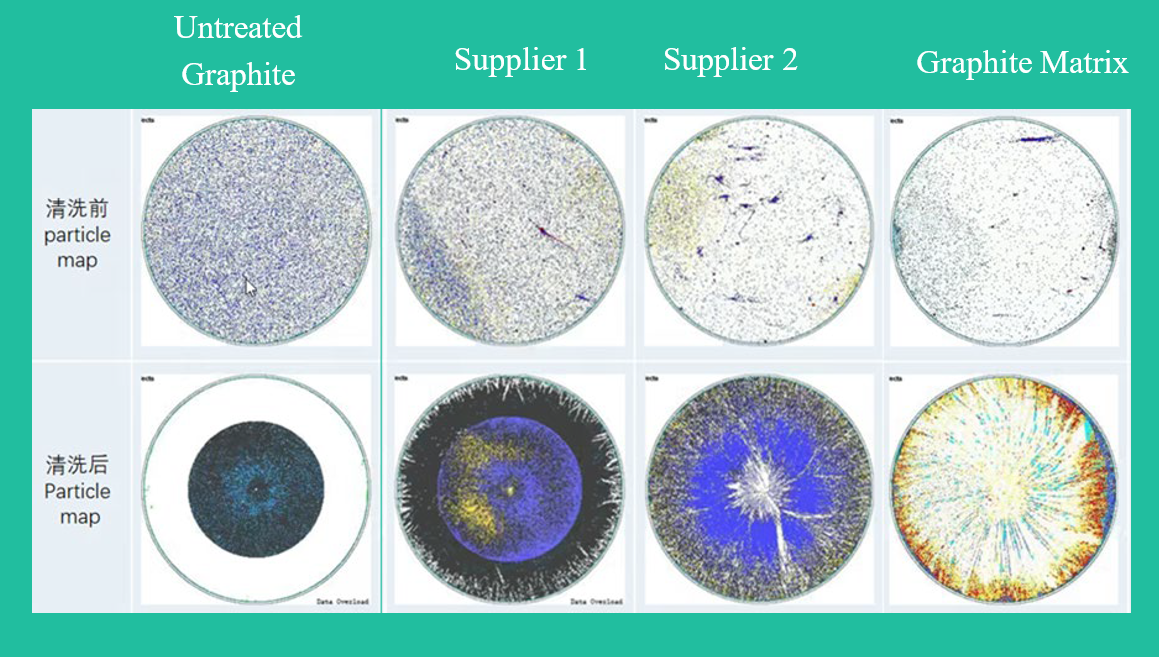

Extended Component Lifespan in AMU Units

The bar chart on the top right compares the lifespan of AMU (Analyzer Magnet Unit) graphite components used in our customer ion implantation system.

Graphite components from Graphite Matrix lasted approximately three times longer than those from other suppliers, effectively reducing

maintenance needs and PM (Preventive Maintenance) frequency.

In addition, after repeated cleaning and sandblasting, our customers reflect that beam impact marks were

significantly reduced in Graphite Matrix's AMU parts compared to other vendors. This demonstrates excellent uniformity and surface stability of our graphite material.

Related News